Call: 08045802292

Metal Powder Coating Services

Metal Powder Coating Services Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 7 Days

About Metal Powder Coating Services

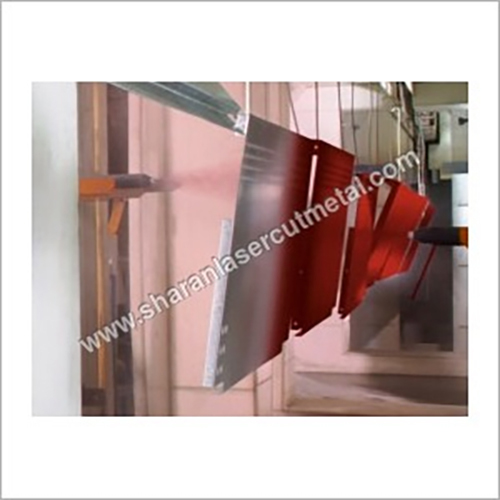

We have secured a distinguished position in the market as a service provider of Metal Powder Coating Services. Equipped with twin painting booths, we provide Metal Powder Coating Services on steel and aluminum fabricated machinery parts. The conveyor operated painting booths can paint up to 3 meters long, 1.5 meters high and 600 mm wide metal components within a short span of time. Being an ISO certified organization, we ensure complete customer satisfaction by using a eight stage pre treatment coating service. As a part of our systematic working process, we conduct quality checking tests like gloss level test, thickness test, visual checks and adhesion test to determine the quality of our coating service.

Precise Finish for Diverse Metal Surfaces

Our powder coating process ensures a smooth and uniform surface finish, compatible with steel, aluminium, iron, copper, and galvanized substrates. Custom coating thickness and curing times are tailored to your projects material requirements, supporting both industrial and commercial applications.

Environmentally Responsible and Certified Quality

We operate in an ISO 9001:2015 certified facility, delivering RoHS-compliant solutions that meet international environmental standards. Our coatings provide long-lasting protection, high abrasion resistance, and excellent adhesion strength, minimizing the need for frequent maintenance.

Versatile Service Options and Fast Turnaround

Select from glossy, matte, textured, or satin finishes in multiple RAL shades. We offer flexible service modeson-site or off-sitewith lead times typically ranging from 3-7 days, accommodating unique project schedules and requirements across India.

FAQs of Metal Powder Coating Services:

Q: How is the metal powder coating process carried out?

A: Our powder coating process uses electrostatic spray equipment to apply powder to metal substrates such as steel, aluminium, iron, copper, and galvanized surfaces. The coated components are then cured at temperatures between 180C and 200C for 15 to 30 minutes, depending on the metal type, ensuring a smooth and durable finish.Q: What benefits does powder coating offer for industrial components?

A: Powder coating provides high abrasion and corrosion resistance, excellent adhesion strength, and a long-lasting finish. Its smooth, uniform surface reduces maintenance requirements, and various custom finishes enhance aesthetic appeal while meeting rigorous quality standards.Q: When can I expect my coated metal components to be ready?

A: Typical lead times for our powder coating services range from 3 to 7 days, depending on project requirements, substrate quantity, and chosen finishes. Larger orders or highly customized requests may require slightly extended schedules.Q: Where is your powder coating service available?

A: We provide metal powder coating services across India, operating as an exporter, supplier, manufacturer, and service provider. Both on-site and off-site service modes are offered to suit customer preferences and logistical needs.Q: What types of finishes and colors are available for powder coated metals?

A: We offer a variety of custom finishes including glossy, matte, textured, and satin. Clients can select from multiple RAL shade options to match specific design or branding preferences for their metal components.Q: Is your coating process environmentally compliant and certified?

A: Yes, our facility is ISO 9001:2015 certified, and our powder coating process is RoHS compliant, ensuring environmentally responsible practices and internationally recognized quality standards.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese